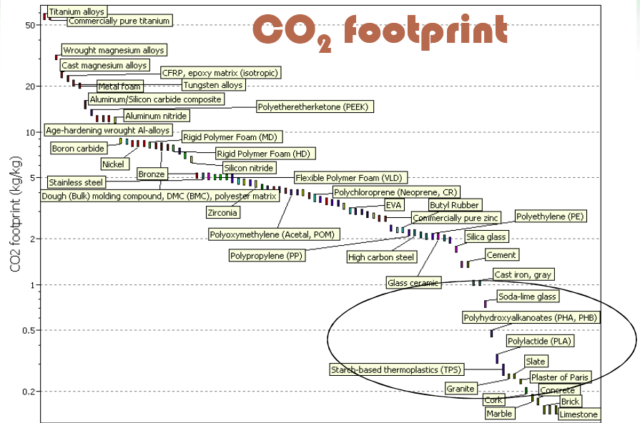

I’m starting a journey of discovery into 2 things. The way of bamboo and the way of the bike frame. I plan on making 2 prototype bikes with mostly bamboo frames. One with lugged steel joints, the other with woven fibre and epoxy resin. Based on the successes or failures of each prototype I then plan on producing custom frames for demanding customers who’re after something a bit different in their daily ride.

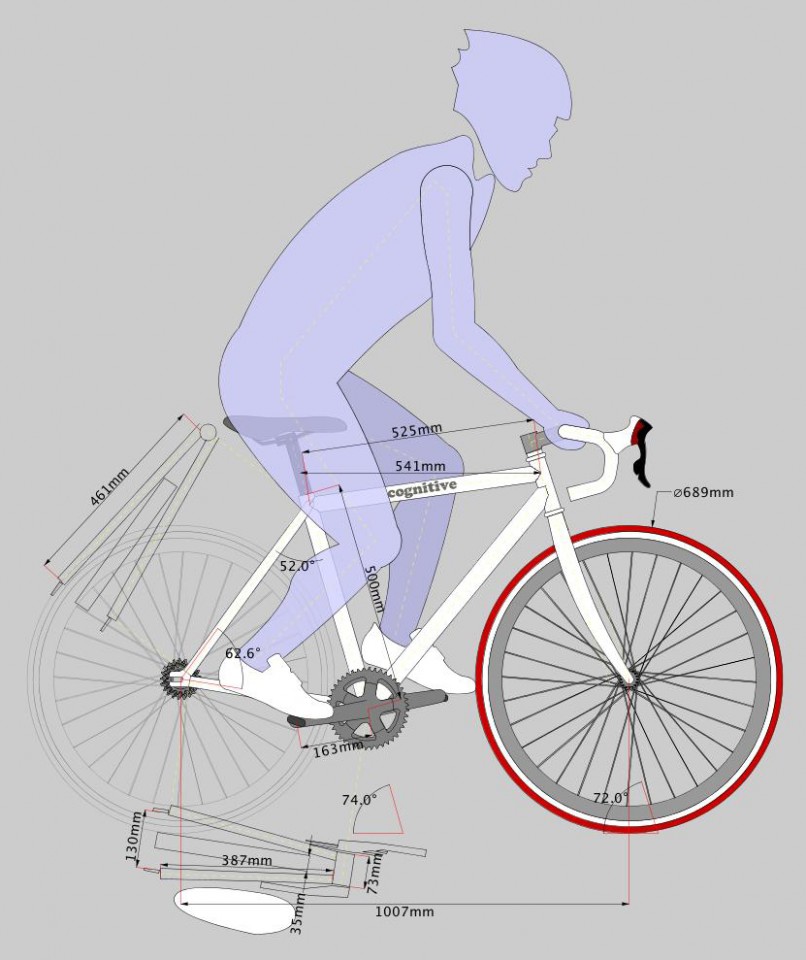

The prototype bikes are going to be simple single-speed flat-bar commuters, similar in geometry and style to a Giant CRX or Apollo Blade.

Using BikeCAD and a tape measure I’ll measure and design the requirements for each frame, and decide upon what’s going to be bamboo, and what’s best left to steel or other material.

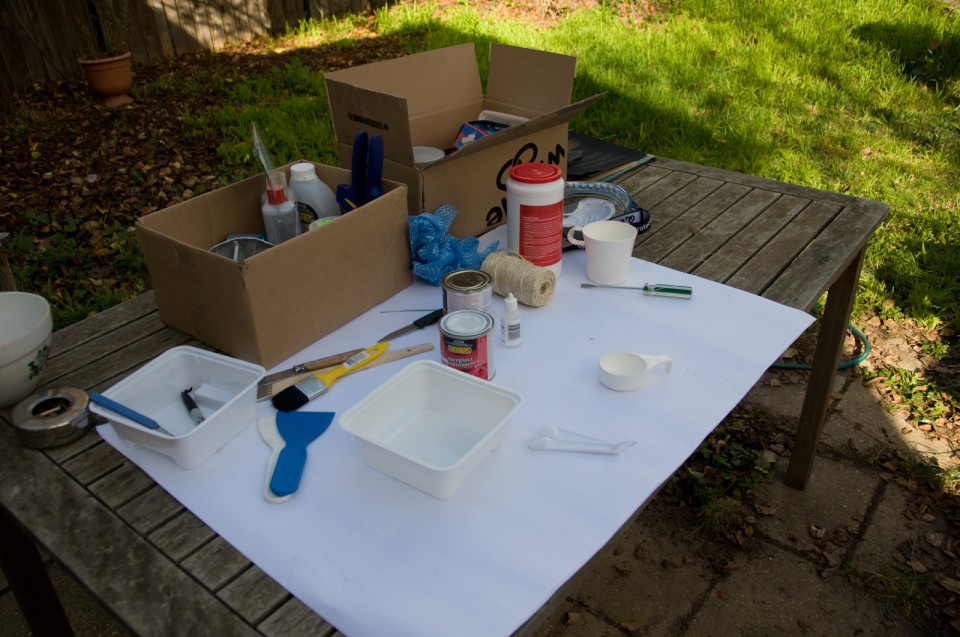

I’ve sourced enough bamboo (from my kind parent’s garden) for two bikes. But before I can use it I need to cure and treat it against bugs, mould and cracking. Hopefully I’ve got enough to play with after all the experimenting!

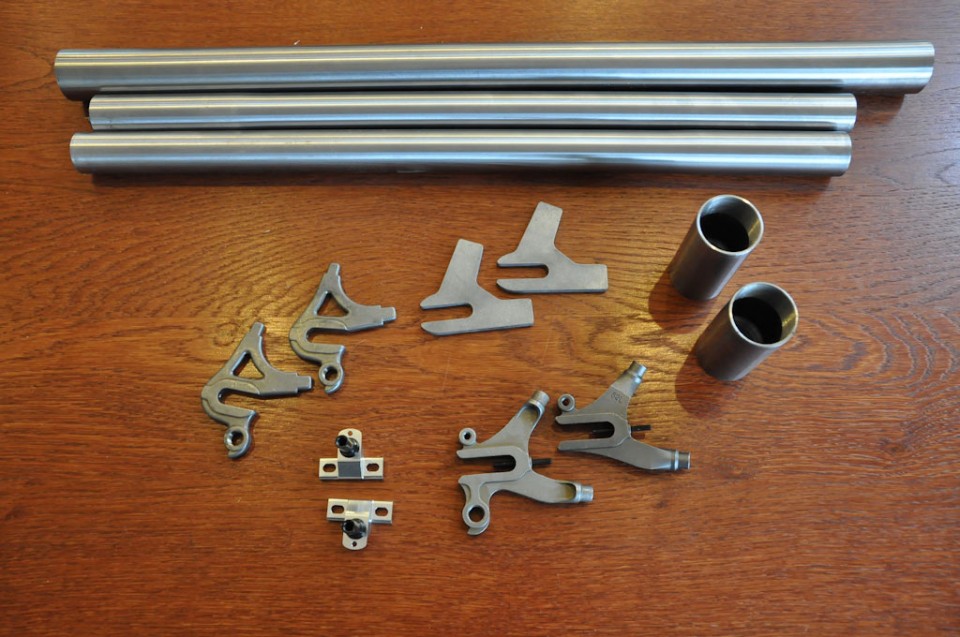

After treating the bamboo I’ll be examining diameters to see which will best suit the various parts of the frames. From there I’ll explore the joining process with metals and other materials.

Protecting the bamboo against the elements will also require some research. What oils, paints or varnishes can I use?

This site will seek to be a resource of information about bamboo bikes as well as a documentation of the building process from start to finish for others to follow.